Cases

Tampere Tramway

Published 16.01.23Tehomet supplied nearly 700 joint use poles for the Tampere Tramway

The tram in Tampere is not a entirely novel concept

The idea for the tram in Tampere arose over a century ago. In 1907, the first proposal was made and after many stages, the idea became a reality in August 2021, when the operation of Tampere’s tram eventually began.

The construction of Tampere’s tram is taking place in two phases. In the first phase, the tramway was implemented from Pyynikintori to Hervanta and from Tays to Sori Square between 2017 and 2021. The second phase of the tram is being built from Pyynikintori to Lentävänniemi incrementally and is expected to be completed by 2024.

The construction of the tram entailed a comprehensive renovation of the street space in the center of Tampere. Trees were removed, the street space was excavated from wall to wall, and virtually all of the infrastructure beneath the street was replaced.

Investigations, plans, and proposals

A city plan for the central area of Tampere has designated the Tammerkoski area as a historical district, which must be taken into account in all construction. The appearance of the old buildings and the character of the area were also taken into consideration in the design of the poles.

Initially, the project’s goal was not to design a completely new pole model. The designers investigated the possibility of utilizing an existing two-part pole model, but it was deemed unsuitable for the purpose. The old pole model was structurally plate-like, heavy in appearance, and closed on one side, and not all lighting technology could be accommodated within it.

Therefore, a decision was made to design completely new joint use poles for Hämeenkatu. A challenging list of requirements and desires was presented to the designers.

A massive, sleek, distinctive, and timeless pole

The new poles were to serve as attachment points for not only lighting poles but also as support cable holders and event lighting. During the design phase, only a reservation for event lighting was known, and calculations were made for structures weighing 70 kilograms.

The same pole had to combine a massive technical space and sleek exterior form. The poles had to accommodate multiple electrical and communication devices as well as event lighting technology. The poles had to be visually striking, featuring distinctive design. The poles were not allowed to cast shadows or obscure the surrounding buildings, so they had to be open.

In terms of lighting, the criterion from the beginning was that glare would be minimized as much as possible. The pole spacing is dense in Hämeenkatu, which allows for optics and lenses that do not spread light far to the side. Lenses were chosen for the lights that prevent glare and distribute light more evenly. Additionally, separate lights were needed for the pedestrian and bike path and for the façades of buildings.

The street and technical solutions are part of the urban space for decades, if they are well maintained. Once erected poles are a long-term solution and therefore the overall design had to be timeless. The design language was not to be based on passing trends.

The Finnish nature and history were sources of inspiration

It became clear very quickly that no ready-made pole that met Tampere’s requirements could be found, so WhiteNight Lighting’s designers Arto Heiskanen and Joonas Saaranen began designing poles from scratch.

The designers sought ideas for the poles from history, specifically from the still-existing “Rollikka” poles found in Tampere’s street views. Rollikka buses were trolley buses that operated in Tampere from 1948 to 1976, powered by electricity. Cross-shaped steel poles were erected for the electric wires.

Trolley bus, commonly referred as Rollikka, in Hämeenkatu during the 1950s. Photo: Wikipedia.

Important sources of inspiration for the new poles were the old trolley poles in Tampere.

Designers aimed to incorporate an organic, nature-inspired design into the poles. Thus, ideas were sought from the natural world. A Finnish designed coat rack resembling a tree branch, standing in a corner of the office, was a prime example of how straight metal can be transformed into an organic shape through careful design.

In the initial pole designs, the organic form of nature was clearly visible, but gradually the shape became more streamlined as the requirement for excellent stability from a shared pole increased. Stress calculations and wind loads in the structural design led to modifications of the original plans. The development process was ultimately lengthy and multi-faceted, and a variety of both perforated and more open versions were explored during this process.

The final corkscrew pole model emerges

The decisive insight into the structure and appearance of the pole came while working with a parametric design program. The designers noticed that when the tops of the vertical profiles placed at the corners were turned relative to the bottoms, the impression of a corkscrew pole was created without bending the profile. Joonas Saaranen remembers the moment of enlightenment:

It was one of those moments when we realized that we might have stumbled upon something groundbreaking! When you pass by the pole, it looks like it’s alive. From one angle the pole is flat and from another it looks narrower in the middle.

Project manager Jouni Lehtomaa is delighted with the reference to history in the design language:

I was particularly fond of the simplicity of the pole, and on the other hand, four tubes are part of the Tampere pole family. There are other solutions with four tubes here, which are straight and this is clearly part of the same family, and in that way it somehow embodies Tampere’s style in its own way.

The poles on Hämeenkadu street look complex and curved around their axis, but upon closer examination, the vertical profiles are one straight tube with cross-braces of different lengths in between. With this structure, the poles were made sturdy enough while still being open.

The design of the poles was illustrated to the project participants multiple times using 3D models and VR glasses. The scale and overall appearance were conveyed to all very concretely with glasses on, in the “right” environment.

Joonas and Arto emphasize that in all design, ideas should be presented as concretely and impressively as possible. An excellent plan is often left unrealized if it is presented haphazardly or with unfinished materials. A good idea needs a worthy presentation.

More detailed design

Once the design language and scale had been agreed upon, the team moved on to more detailed plans and technical solutions. The base of the pole seemed to expand throughout the process as a lot of different technology had to be accommodated there. Project manager Jouni Lehtomaa, recounts:

It was quite surprising how much closed space was needed in the lower part of the pole! It felt like it was growing all the time as new requirements came up. I was a bit worried that the lower part would become too massive, but it eventually fits in well with the overall design.

The height of the pole’s base was originally designed so that the decorative light illuminating the pole at the top of the base is above the eye level and does not cause glare. Safety was also a factor in the design: it is not easy to climb the pole if there are no ladders all the way up.

The tensioning mechanisms for the tramway wires did not cause much of a challenge, but the greatest stress according to calculations came from the fact that the 70-kilogram light curtains had to be suspended on a small hanger so that they do not touch the tramway wires. This transverse tension resulted in more cross-braces and they became more stable than intended.

The old trees had to make way

Mika Heikkilä, System Manager of the City of Tampere, recalls the technical constraints in the public space. The trees that had landscaped the edge of Hämeenkatu street had to be cut down to make way for the renovation, and a new growing environment was built for the new trees.

For the trees along the street, there were two challenges. One was that the trees did not align with the pole spacing. The pole spacing is based on certain technical requirements set by the tramway, and since the spacing of the trees did not match that, they would have had to be moved anyway.

The second challenge was that the trees’ growing environment was originally poor, so the trees were not in good condition. In this renewed solution, a new growing environment was built for the trees so that they can grow better in the future.

Tehomet consulted and supplied the shared-use poles together with its partners

The designers of the tramway poles were in contact with Tehomet early on to determine the feasibility of their plans. Together they quickly found a cost-effective and suitable manufacturing method. After the approval of the prototype made by Tehomet, full-scale production could begin.

The cross-braced pole structure consists of several laser-cut, different-sized cross-braced parts. A customized jig was built at Tehomet’s Kangasniemi factory for welding the poles, which allowed for the flexible rotation of the massive pieces as the work progressed.

Mika Heikkilä emphasizes the importance of quality and longevity in such significant investment projects. Tehomet’s partner, painting service FSP, recommended the Plascoat surface treatment method for the tramway poles. Plascoat, especially when combined with hot dip galvanizing, provides an extremely long-lasting protection against corrosion.

Tehomet was the first in Finland to take advantage of Plascoat’s excellent properties in its steel products. The first projects were playground poles for daycare centers – Plascoat surface does not stick to the tongue in freezing weather. The method of application is the same as with powder coatings, but it creates a thicker and truly permanent film.

Tehomet took care of the delivery of the finished poles according to the customer’s wishes. The finished poles were delivered in small batches as precise deliveries, usually during the night, to minimize disruption to traffic. The poles were packed into racks built for these poles and delivered directly to the site, where the poles were lifted into position for the electrical installations.

Light separates the path for pedestrians from the tram and bus roadways

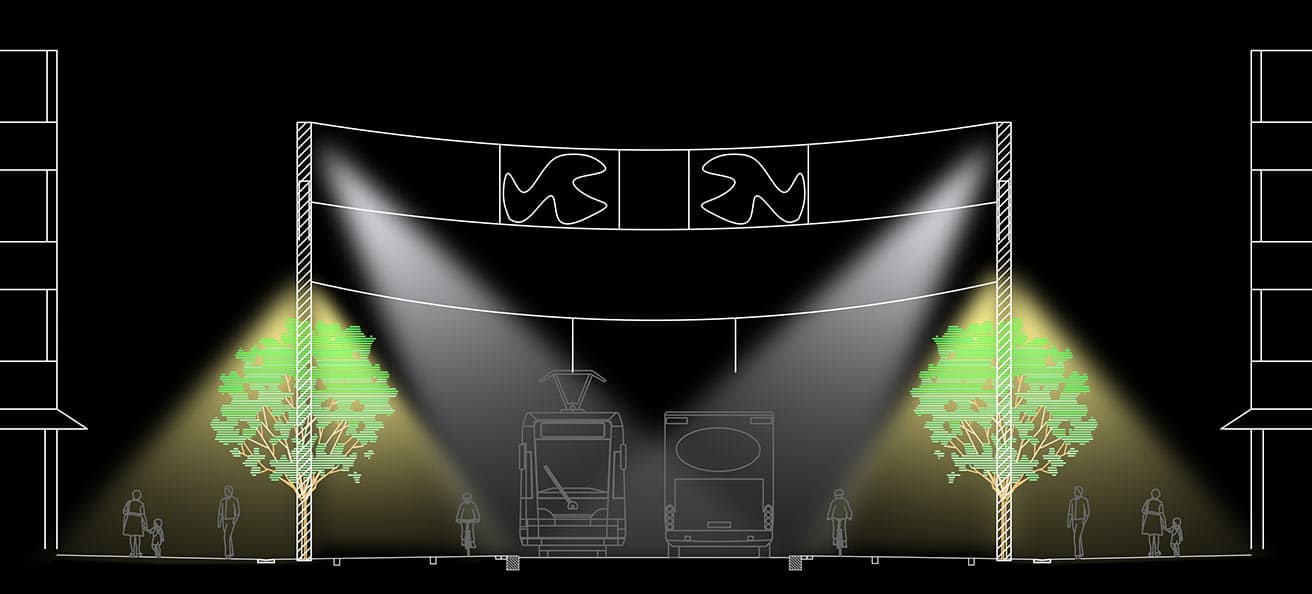

The new lighting on Hämeenkatu conveys different messages through variations in color temperature. In the central areas where buses and trams operate, the light has a cool temperature of 4000 Kelvin, while in areas designated for pedestrians, the light is lowered and has a warmer colour temperature of 3000 Kelvin. Additionally, the crosswalks are highlighted by warm light, and projectors are used to precisely illuminate the necessary areas.

At the forefront of the revamped Hämeenkatu

The designers of the poles, Joonas Saaranen and Arto Heiskanen, are pleased with the successful completion of the challenging task. The collaboration between the designers, manufacturer, and other participants has been smooth, which is reflected in the successful outcome. The new lighting and poles have not only improved the appearance of the street, but also the overall atmosphere.

The residents of Tampere are probably very satisfied with the completion of the new main street. It was a big deal when the mature trees were gone, that oh, the beautiful trees were gone and replaced by these steel poles. But once the new trees grow and soften the space…

Walking on the street, the silence is significant now that the cobblestones have been removed. It feels more high-quality in my opinion.

The Project Manager, Jouni Lehtomaa, exudes pride and contentment.

I am pleased that we made these somewhat more traditional poles rather than going with the previous poles, which were more about design than being poles. These new ones are poles that have been designed.

The pole’s own meaning and purpose should come through in the design, and yet the pole can still look good. It’s sustainable design, and not tied to trends. These new poles resemble trolley poles and therefore reflect history.

We decided that the entire Hämeenkatu would be with these poles, but they will not be put anywhere else. If similar poles start to be put everywhere, it will suffer from inflation and start to clash. But in this scale, these poles are just in the right place. Hämeenkatu is the one that is known from Tampere, and in this way its uniqueness is emphasized.

Yes, I am proud of what we achieved. Creative workers should be proud of their work. Then you know that you have worked with all your heart, responsibility and commitment.

The luminaires used on Tampere’s Hämeenkatu.

Light traffic 3000K, Fagerhult Custom light fixture, with Vialume lens technology

Roadway 4000K, Fagerhult Evolume, with custom frames

Pedestrian walkways 3000K, We-ef FLC 230 projector luminaire

Decorative pole light, Savled RGBW D270

The following professionals involved in the project have been interviewed for this customer story.

Arto Heiskanen, Lighting Designer, WhiteNight Lighting

Joonas Saaranen, Lighting Designer, WhiteNight Lighting

Jouni Lehtomaa, Project Manager, Hämeenkatu planning project, Ramboll (retired)

Mika Heikkilä, System Manager, City of Tampere

Tomi Pasanen, Production Manager, Tehomet

WhiteNight Lighting

Named after the Finnish summer midnight sun, WhiteNight Lighting is a design studio founded in 2013 by Joonas Saaranen and Arto Heiskanen. The duo strives to create technically cutting-edge projects and deliver outstanding customer experiences.

Saaranen studied industrial design at the University of Lapland, where he was deeply impressed by the natural light in the area. The dark gloom of autumn gave way to a glowing light with the first snowfall. In spring, the sun gradually rose higher and higher on the horizon, and in summer it illuminated not only the day but also the night. The natural light of the North, the alternation of darkness and light, has made an indelible impression on the duo and is reflected in their design.

Share this article

Location: Tampere, Finland

Construction year: 2017–21

Used in: Traffic Lighting

Designer: WhiteNight Lighting

Photographer: Ilpo Aalto and Skyfox