About our steel products

Raw material

Tehomet mainly uses low-silicon structural steel as the raw material for its steel light poles. A low silicon and phosphorus content ensures an excellent base for a neat and high-quality galvanized surface.

Pole structure

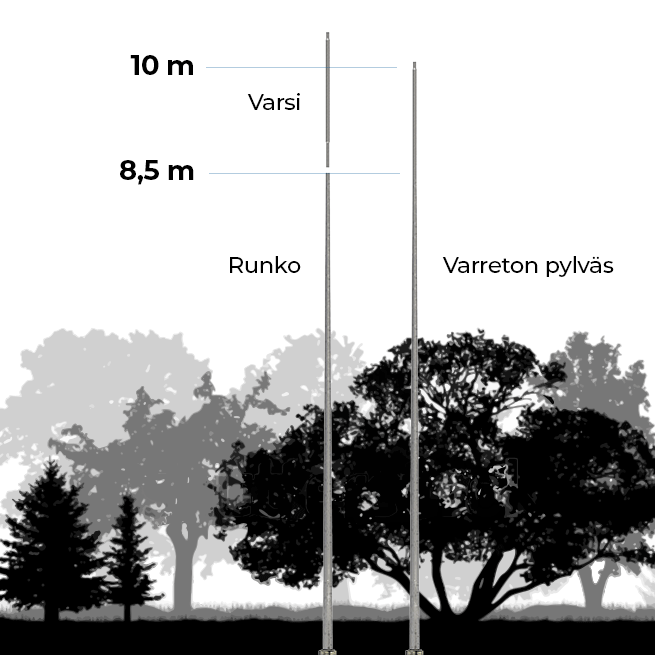

A pole will always have at least a shaft, which may be conical, stepped or even cylindrical. An arm or cross arm will often be attached to the shaft.

Production

Tehomet’s steel products are manufactured at our own factories, either in Kangasniemi, Finland or Kiiu, Estonia. The Kangasniemi factory specializes in small series production and custom products, while the Kiiu factory manufactures standard products for the Baltic market in particular.

Hot-dip galvanization

Hot-dip galvanization is the most common surface treatment for steel products. A zinc coating will protect steel from most environmental conditions throughout a product’s lifecycle without requiring any kind of maintenance. Under normal conditions, a hot-dip galvanized product will have a service life of more than fifty years.

Packaging steel products

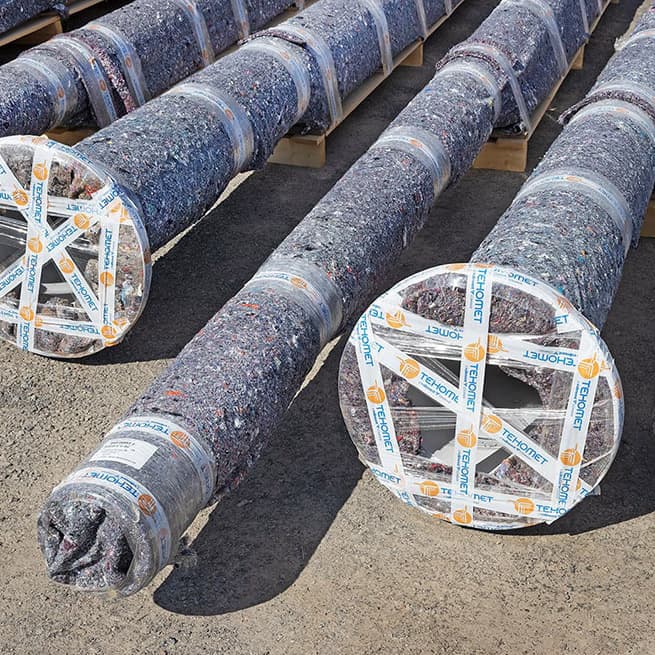

Our default approach to packaging is to produce as little waste as possible on construction sites. That’s why Tehomet’s products are always packaged on a project-by-project basis in accordance with the product type and mode of transport.

Maintenance

Tehomet’s steel poles are hot-dip galvanized to ensure effective and long-lasting protection. A hot-dip galvanized steel surface rarely needs any maintenance.