Wooden pole manufacture

Tehomet’s wooden light poles are manufactured at our Parikkala factory using glulam beams made of PEFC-certified Finnish pine. Read more about the timber we use on the “Raw materials for wooden poles” page.

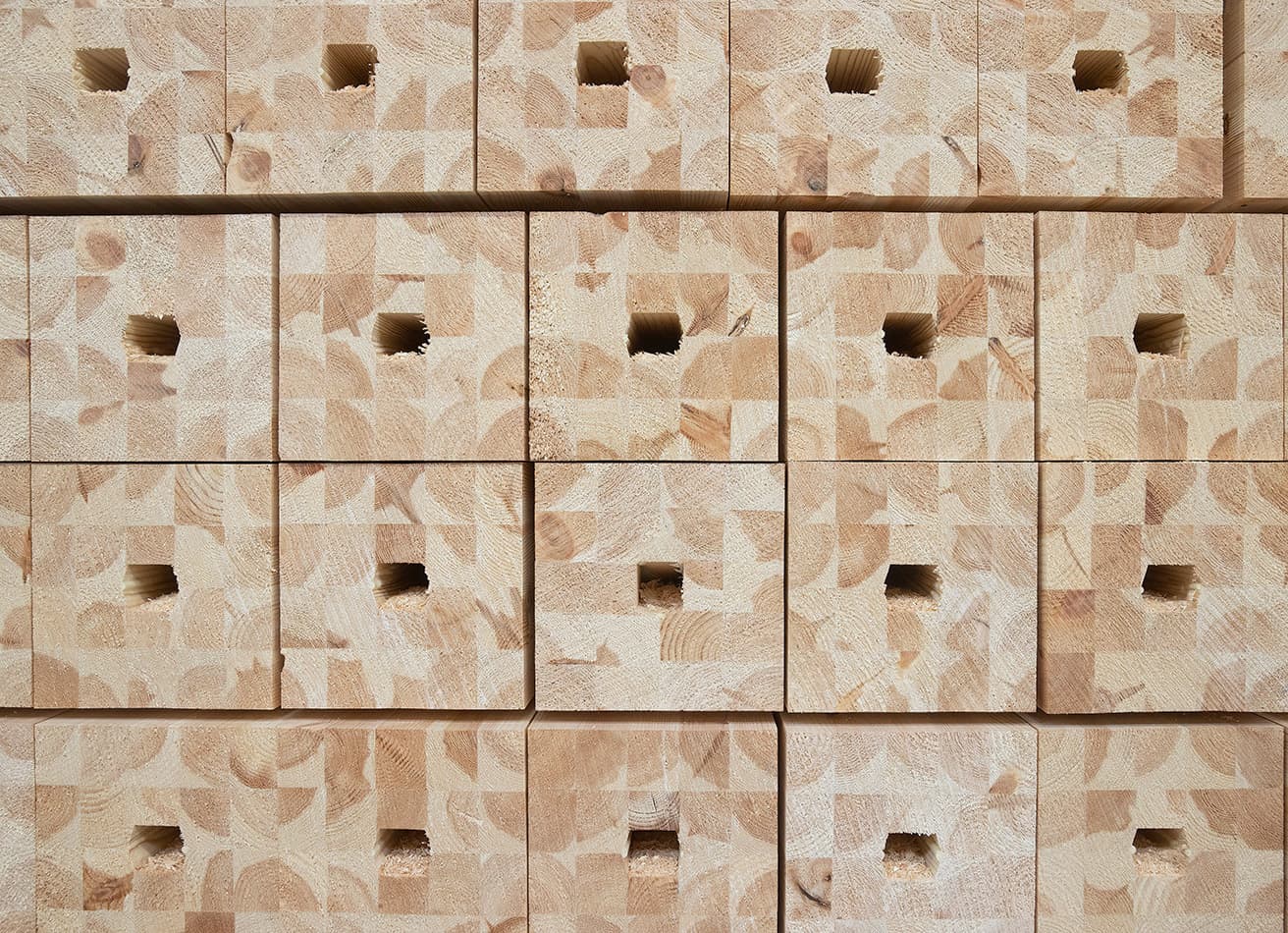

The glulam beam blanks come predrilled with a central hole for cabling. This central hole can be widened as required, from either the base or top section alone or along the entire length of the pole. A wider feedthrough will be required for drawing several cables through the shaft.

The main stages of the manufacturing process of wooden poles

Machining into the correct shape

The first phase of the manufacturing process depends on the cross section of the pole. If it is round or conical, the process will begin with CNC machining. A square or rectangular pole will be planed. The pole will already acquire its characteristic shape at this stage.

Machining adapters for metal components

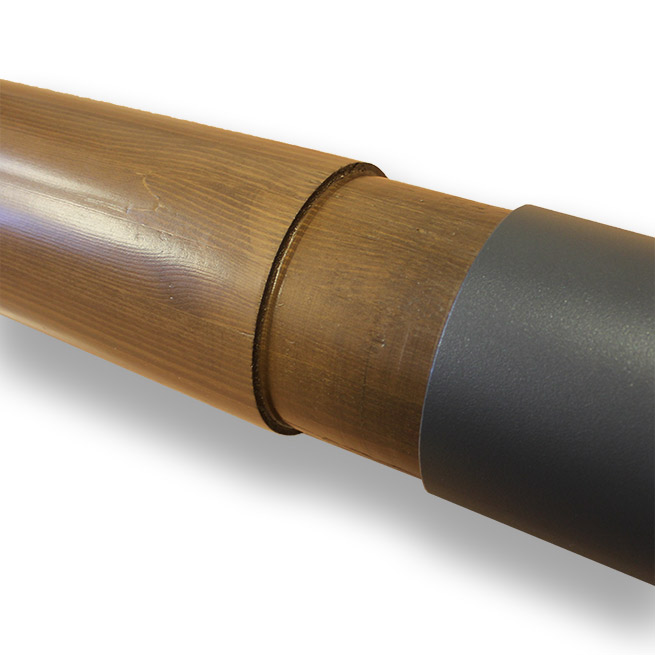

After the pole has been machined into shape, adapters for mounting the metal base and top sections will be worked into the wooden base and top sections.

Finishing the wooden sections

The finishing stage begins with repairs to any visual defects in the wooden poles, such as dry knots. The wood will then be sanded to create a smooth, flat surface for treatment.

Protecting the wood with surface treatments

Wooden light poles are surface treated in accordance with a coating system developed by Teknos. The surface of the wood is first treated with anti-mould protection. After this layer has dried, the tinted coat specified in the order is added on top of it.

Another drying stage follows, after which the pole is returned to the painting line where it is sprayed with the outer surface layers of the painting system: two more coats of water-soluble, alkyd-acrylic-based varnish with UV radiation blocking properties.

Finishing and packaging

Once the surface treatment layers have dried, the assembly and packing stage can begin. During this stage, the wooden surfaces are protected with plastic and cardboard for further processing and transport.

During assembly, the metal components are attached to the wooden section of the pole in accordance with the technical drawings. The pole is then ready to be packed on a wooden pallet, which will be protected by plywood sheets and plastic for transport.

Read more about the packaging and transport of wooden poles.